Hoplites agency

We coordinate garments manufacture, managing each step of the process maintaining daily contact with various carefully selected manufacturers which we chose by exploiting years of experience in identifying the right partners who possess the necessary high end requirements, aiming to completely satisfy the customer’s needs.

We lead, assists and coordinate the various stages of the manufacturing process using methods developed and improved during over 30 years experience.

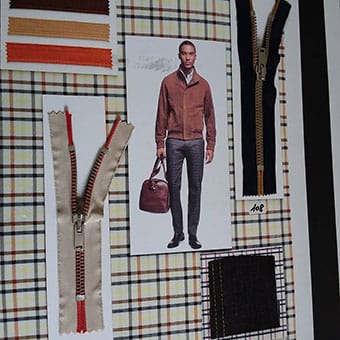

Moreover, very important, we can search and provide the fabrics and the trims (such as buttons, zips, and so on) on behalf of our customers according to their indication.

Technology, work culture, innovative organization

- Technology: by developing an extensive database of information we are able to solve problems quickly and efficiently, making real-time decisions thereby optimizing the response time.

- Work Ethic: by constantly striving for better results to achieve total excellence and professionalism

- Innovation: the ability to adapt and customize the service tailored to the individual needs of each customer and care about the working environment of employees maximizing their output and quality of work.

- Great care so that our affiliates allow their employees to operate in healthy and purposeful environments, in order to maximize the predisposition of each in offering qualitative work performances

- It is a fact that all our partners have constantly improved over time and that our customers reconfirm the collaboration relationship with Hoplites, recognizing our indispensability

A single technical contact

Allowing the customer to interact with a single contact, always within reach, enables better control so that questions are answered quickly and succinctly.

Moreover, we send a weekly status report accompanied by photos if required.

Our goal is to be your right arm throughout the process: your satisfaction will be the ours.

Manufacturing phases of an industrialized tailoring garment

If you have always wondered how the clothes we wear daily take shape, in this article you will discover the secrets that hide behind the art of industrial tailoring and you will go into the processing phases of an industrialized tailoring. Creating clothing is a complex operation consisting of several phases. Let’s see what they are and what they consist of.

Pattern study and design

The paper pattern is the basic tool from which you start to give life to a garment: the name derives from the fact that in the past the paper patterns were handmade by the pattern maker who, with the use of drawing square and ruler, was drawing the garment’s shape on paper, basing on standard or real measures. In addition to the drawing of the garment itself, the pattern was showing fundamental indications necessary for the realization, such as dimensions, shape, seams, tools to be used, and much more. Creating patterns was not a simple operation at all, on the contrary, it was a complex project that required patience and dedication. Nowadays, to increase efficiency and precision, companies tend to use digitized patterns based on measures whose size grading are based on computer programs managed by pattern makers capable of evaluating the right proportions in relation to the fit requested by each specific brand; but, if necessary, they are obviously also able to give life to new projects starting from drawings on old -fashioned style paper patterns proposed by the client himself. In this case we speak of digitization of the pattern.

Patterns’ Digitization and Size Grading

The technology has totally revolutionized the way of designing clothing: modern companies have in fact an advanced pattern making software called CAD (Computer Aided Design), which allows you to create, entirely by the computer, virtual patterns on the basis of measures or indications provided by stylists themselves, without going from manual work. In the event that the customer only has paper patterns, we proceed directly to the digitization phase: at this stage, through a camera, the computer is able to scan and copy the perimeter lines of the paper pattern and to transport everything to CAD, where the software, managed by the pattern maker’s experience, will create the grading of the sizes based on the inputs that the pattern maker himself will decide to provide time after time. The CAD program also allows you to store special data and information, constituting a precious archive that remains client’s ownership.

Laying and cutting of the fabric

Thanks to a special machine called a Laying machine, the fabric rolls can be transformed into cutting mats, which are then lightened by the blowing tables to allow a more agile and practical movement of the same.

At this point, the cutting mats are processed by the automatic cut, a totally autonomous machine which, after receiving settings and work commands, cuts the fabric with a robotic blade. The use of technological machinery allows in this case to reduce production costs and to produce large quantities of material in a safe and infinitely more precise way. Of course, alternatively, Hoplites S.r.l. can also make use of manual cutting where the quantity or type of fabrics or garments makes this technique necessary or more appropriate, based on the experience gained over the years by personnel specialized in this essential function, using manual tools such as scissors and cutters. This too is part of the charm of true made in Italy.

Sewing

The sewing is a delicate phase aimed at giving life to the clothing garment as we know and find it in boutiques and shops. Once the boss has taken shape thanks to the sewing, which can take place both with sophisticated machinery guided by the hands of expert workers, and with the patient and traditional work of staff capable of carrying out hand stitching steps, thanks to technical knowledge handed down through generations, we proceed by control of all the finishes for an accurate work and in a workmanlike manner. All staff, manufacture laboratories and services used by Hoplites S.r.l. they are exclusively Italian, indeed even almost all are placed in Puglia, that is the same region of Hoplites S.r.l. for an accurate and extremely efficient management of the work, which guarantees a 100% Made in Italy product of the highest quality level.

Packaging

Once ready, the garment can finally be packaged appropriately. However, there are different types of packaging: the most common type sees the garment individually wrapped in an envelope and then placed in a box where the items are managed according to sizes and styles.

At this point the work is complete and the garment is ready to be packed and shipped!